5 Project Management Methodologies and Their Risks: Part 4 – Lean

Lean Project Management is useful to optimize profit margin, reduce waste, and improve customer experience. Although originally developed for manufacturing, many companies are turning towards Lean methods in almost any industry.

This is the last part of the whole project management methodologies series.

In the first three parts, we looked at:

- the traditional Waterfall approach,

- the Agile methodology in general,

- and the Scrum and Kanban project management.

Methodology 5: Lean Project Management

The Lean Enterprise Institute (LEI), founded by James P. Womack and Daniel T. Jones in 1997, is considered the go-to resource for lean wisdom, training, and seminars.

Lean Project Management is focused on value delivery from the customers’ perspective, cutting down project waste to optimize efficiency and continuously improving.

Simply, lean means creating more value for customers with fewer resources.

From our experience, Lean is rather a philosophy that needs to be adopted by the whole organization rather than used in isolation as a pure project management. It is mostly used in combination with other project management methodologies that are executed as Lean.

It is recommended that managers and executives embarked on lean transformations think about three fundamental business issues:

- Purpose: What customer problems do we solve?

- Process: How will the organization assess each major value stream to make sure each step is the right one (according to the Lean criteria) and that all the steps are linked?

- People: How can an organization ensure that every important process is monitored, evaluated in terms of business purpose and lean process? How can everyone touching the value stream be actively engaged in operating it correctly and continually improving it?

3 Types of Waste

Lean was originally created by Toyota to eliminate waste and inefficiency in its manufacturing operations.

So what are the types of waste? What are the types of so called non-value-added components in any process?

Lean project management identifies three types of waste; muda (waste), muri (overburden), and mura (unevenness), also known as the 3Ms.

Muda (waste) is the direct obstacle of flow. Simply taking out the muda does not work. Usually, there is a reason why the muda is there and this reason often has to do with the other two enemies: muri and mura.

One of muda types is transportation. We can never get completely rid of it. Unless we are a baker handing the bread over to the customers directly from the oven. In the end, the ultimate goal is to minimize muda as much as possible.

We also differentiate two subtypes of muda. A muda that does not add any value to the customer (and must be eliminated), and a muda that is a waste but adds value to the customer (like the above mentioned transportation).

Actually, there are seven generally used categories of muda that might add customer value:

- Transportation – excess movement of product,

- Inventory – stocks of goods and raw materials,

- Motion – excessive movement of machines or people,

- Waiting – information pushed to early or not available,

- Overproduction – redundant activities, pushing instead of pulling,

- Over-processing – Scope creep, overtime unplanned, excessive approvals, resources overloaded, excessive reviews, hand-offs, too many iterations…,

- Defects – rework, errors, machine failures, returned goods.

The same holds for muri (overburden). There are always occasions where people have to give an extra additional effort to make the customer happy. The problem arises when you expect this from your people all the time and they soon burn out. The goal again is to minimize muri.

Mura (unevenness) can be found in fluctuation in customer demand, process times per product or variation of cycle times for different operators. This is even more true in project work, where every project is different.

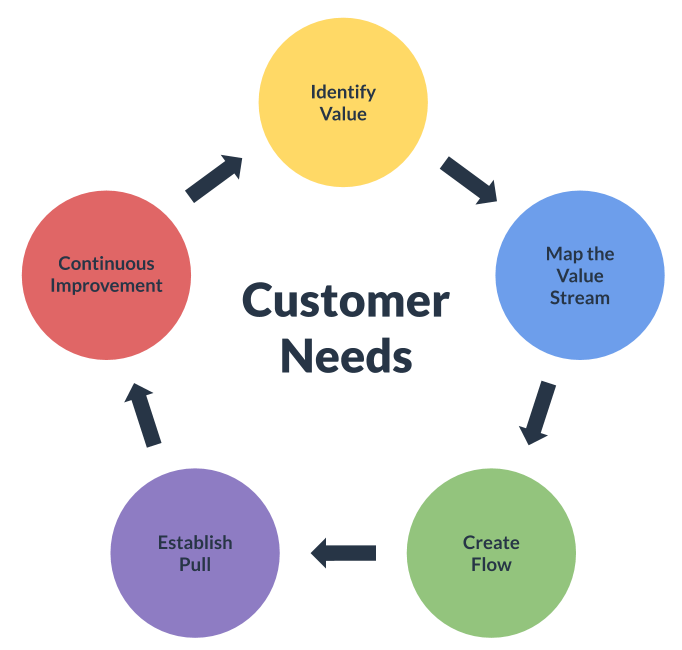

5 Key Lean Project Management Principles

According to the Lean Enterprise Institute, there are five key lean principles: value, value stream, flow, pull, and perfection.

1. Identify Value

Value is anything that the customer is willing to pay for. Identifying value means that you will deliver what your customer needs (in contrast to what they asked for).

Make sure to provide the value at the right time. To describe the value, use the customer’s own language.

2. Map the Value Stream

A value stream includes all the actions, both value added and non-value added, currently required to bring a product from raw material to the arms of the customer or through the design flow from concept to launch (Morgan, 2002).

First, we create a map of the stream – of how the value is produced in your company. This gives us a clear idea of the whole process, what are the inputs, outputs, and waste.

Second, we create a map of an ideal value stream. Then we work on transforming the reality into the ideal state. This is typically done through an improvement plan.

3. Create Flow

Once the value is defined and the value stream is identified, the step here is to create continuous flow by eliminating backflows, scrap, rework and interruptions. No stoppages, no waste is the central tenet here. In analyzing value streams, work will fall into one of three types [PMI]:

- Value-Added Work: Those works are essential changes to product/service. You would look at maximizing this category as there are providing customer value (Form, Fit, Function).

- Value-Enabling Work: Value-Enabling Work is a category that has potential for elimination in the future (with identified improvements) but can’t be eliminated immediately. There are necessary to run the current process. Technology, environment, culture require these activities. You would look at minimizing this category of work.

- Non Value-Added Work: Non Value-Added Work can usually be eliminated quickly and is not dependent on improvement of other areas. This is the work nobody needs and it is pure waste. You would look at eliminating this category of work.

4. Establish Pull

With improved flow, time to market (or time to customer) can be dramatically improved.

This makes it much easier to deliver products as needed, as in just in time manufacturing or delivery. This means the customer can pull the product from you as needed (often in weeks, instead of months).

As a result, products don’t need to be built in advance or materials stockpiled, creating expensive inventory that needs to be managed, saving money for both the manufacturer/provider and the customer.

Or at least save the efforts needed to deliver the product to the very last point in time.

5. Continuous Improvement

Now, you might have walked a long path and achieved some real improvements. But Lean project management is actually never lean until it becomes your culture – your mantra if you will.

The world around us is changing constantly. And we need to accommodate to that. So start all over again and again.

The fact that the perfection cannot be achieved or held for a long time does mean we should stop seeking it.

The Risks

As you can see, every optimization needs to be thought through well. The risk is that companies avoid having a team dedicated for controlling the Lean transformation (that is actually never complete) and let the individual teams do that. This actually introduces muri (and consequently mura) to the teams.

Another risk that we observed is overdoing the Lean thing. They simply cut too deep in the core company flesh if you will. This leads to destabilization of the processes, can take significant time to spot and additional efforts to fix.

It’s a common misconception that the main goal of Lean is to eliminate waste. This is actually not true. Lean is all about delivering as much value as possible with the least amount of investment possible. Eliminating waste is a consequence [Kanbanize].

Risks Caused by Inefficient Actions

When things are going as planned, management’s typical response is reorganization. This can be also very well justified by identifying waste in the teams’ structure. However, this needs to be considered very well. It can create many more problems in communication malfunction, lack of knowledge etc. Reorganization of the teams while a project is running can be lethal to the overall result.

Expediting work is another popular risk introduced in lean and agile project management methodologies. A request for an expedited work can lead to violate existing processes, or skipping important process steps (like quality check). Context switching between several types of work or tasks is known to lead to errors, high stress levels, and eventually a burn out.

Similarly, adding more people to an already delayed project does not make it being delivered faster. The opposite is actually true as the new people need to gain some knowledge and these are the existing team members helping them with that. New team members also create additional communication overhead.

Many companies try to adopt lean project management without a proper investment into the right tooling. This is a necessary step for a successful adoption. The team are required to increase their efficiency (i.e. deliver more) in a more agile manner. The new dynamic environment requires dynamic tooling like a Work Operating System.

Risks Caused by Communication

And these can be both – the lack of communication, as well as surplus of communication.

Hand-offs between teams, clients, suppliers etc. are a typical nightmare. A piece of information is lost at every single hand-off skewing the final result far away from what was originally planned and expected.

Hand-offs also prevent agility as introducing changes to an already running project is almost impossible or via a totally complex and unpractical process.

We recommend to go strictly with the lean project management and follow a smooth flow where there are no hand-offs. Also having a reasonably sized teams helps a lot (see two pizza team).

Wishful thinking is also a frequent cause of having unmet expectations. Everything should be documented and there should be a good reasoning behind each decision, ideally supported by data (you can use ad-hoc reporting for that). Gut feeling decisions and non-communicated expectations are a road paved to hell.

Work that enters the system must leave it somewhere. Either as part of the product or as a waste. If it ends up as a part of the product, then great. If it ends up as part of the waste, you’ll get a valuable piece of information and an idea for value stream improvement. Work must never ever disappear in the system. Just because someone decides they do not want to work on it.

Who is Lean Project Management best suited for?

As stated before, Lean methodology is ideal for any business or organization that is not looking for a process as such but is interested in transforming how they perform their daily operations. It is best combined with Agile methodologies for individual projects’ management.

Summary

It cannot be stressed more that the project management methodologies are not a miracle panacea or a company self healing mechanism. Once there is a problem in project management, just switching the methodology does not make the situation better. Moreover, switching methodologies like a big bang can be disastrous.

Having a slow transformation through something like Agile Waterfall (this will be a topic of one of our future blog posts) is typically a viable and advisable option.

Communication and change management are often the biggest risk factor. Fortunately, you now know what to look out for and where to be careful. However, with the right tooling, any methodology can be successfully driven.

Just remember that all of the methodologies we have introduced in this series are proven by ages and led to many successful product deliveries.